Description

Item description

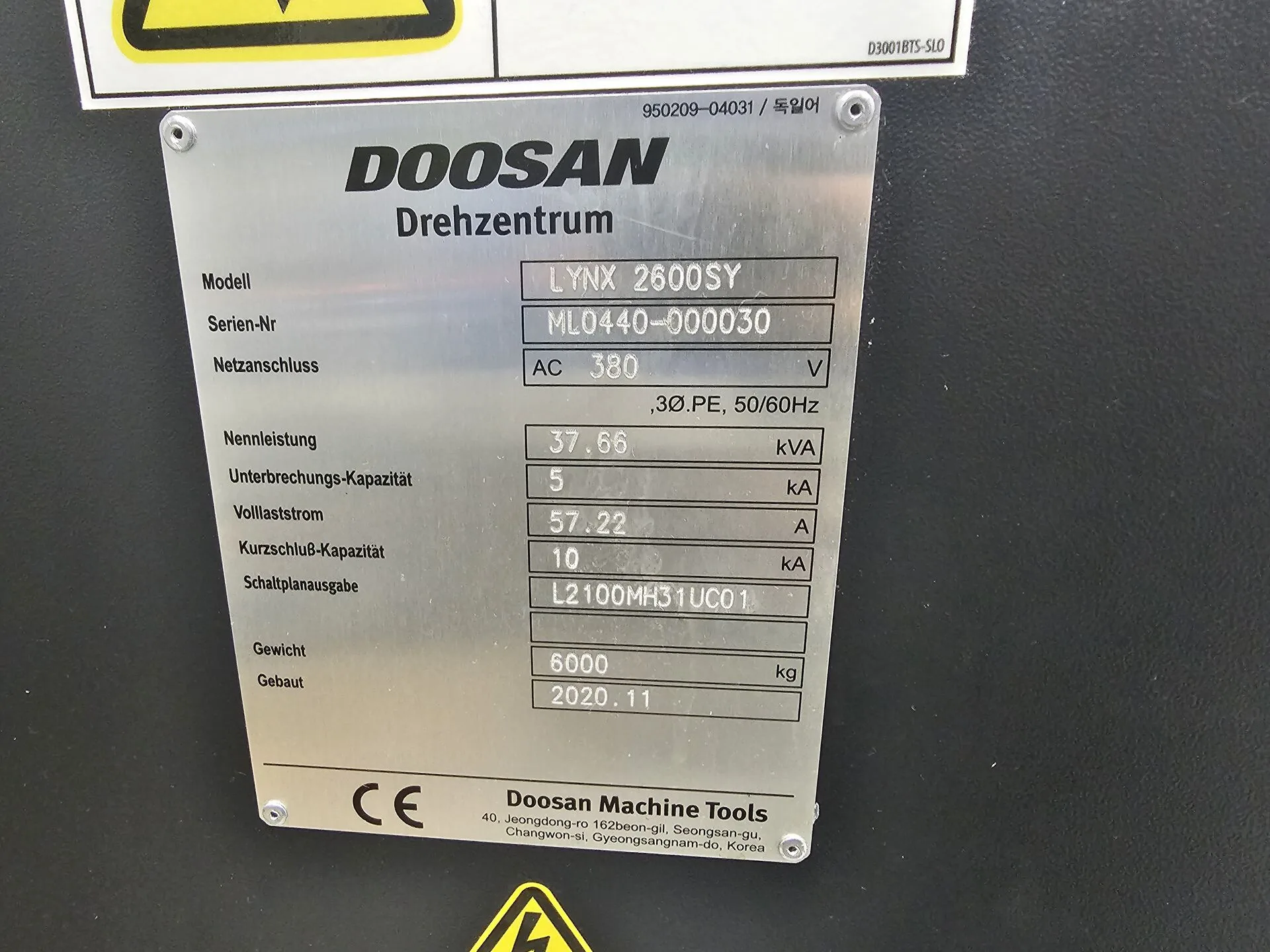

- Serial number: ML0440-000030

- Operating hours: approx. 26,334 hrs.

- Working hours: approx. 13,389 hrs.

- Control: FANUC 0T PLUS

- 15-inch monitor – touch panel

- Memory: 2MB

Technical details

- Max. turning diameter: 380 mm

- Max. turning length: 610 mm

- Bar capacity: 81 mm

Travels

- X-axis: 250 mm

- Y-axis: 105 mm

- Z-axis: 680 mm

- B-axis: 680 mm

Rapid traverse

- X-axis: 30 m/min

- Y-axis: 10 m/min

- Z-axis: 30 m/min

Spindle details

- Max. spindle speed: 3500 rpm

- Spindle power: 18.5 kW

- Spindle bore: 82 mm

- Counter spindle:

- Max. speed: 4500 rpm

- Power: 7.5 kW

Tooling

- Number of tool positions: 12

- Main spindle with 3-jaw chuck: 250 mm / 10″

- 3-jaw chuck counter spindle: 170 mm / 6″

- Turret: 12 PO/24 INDEX BMT55

- Standard tooling: 6x

- Tool holder: 2x

- Axially driven tool: 2x

- Angle-driven tool

- RENISHAW automatic tool measuring hand

Additional features

- CNC Autodoor

- Double hydraulic pressure on the main spindle (low to high pressure for machining thin parts)

- Automatic shut-off function

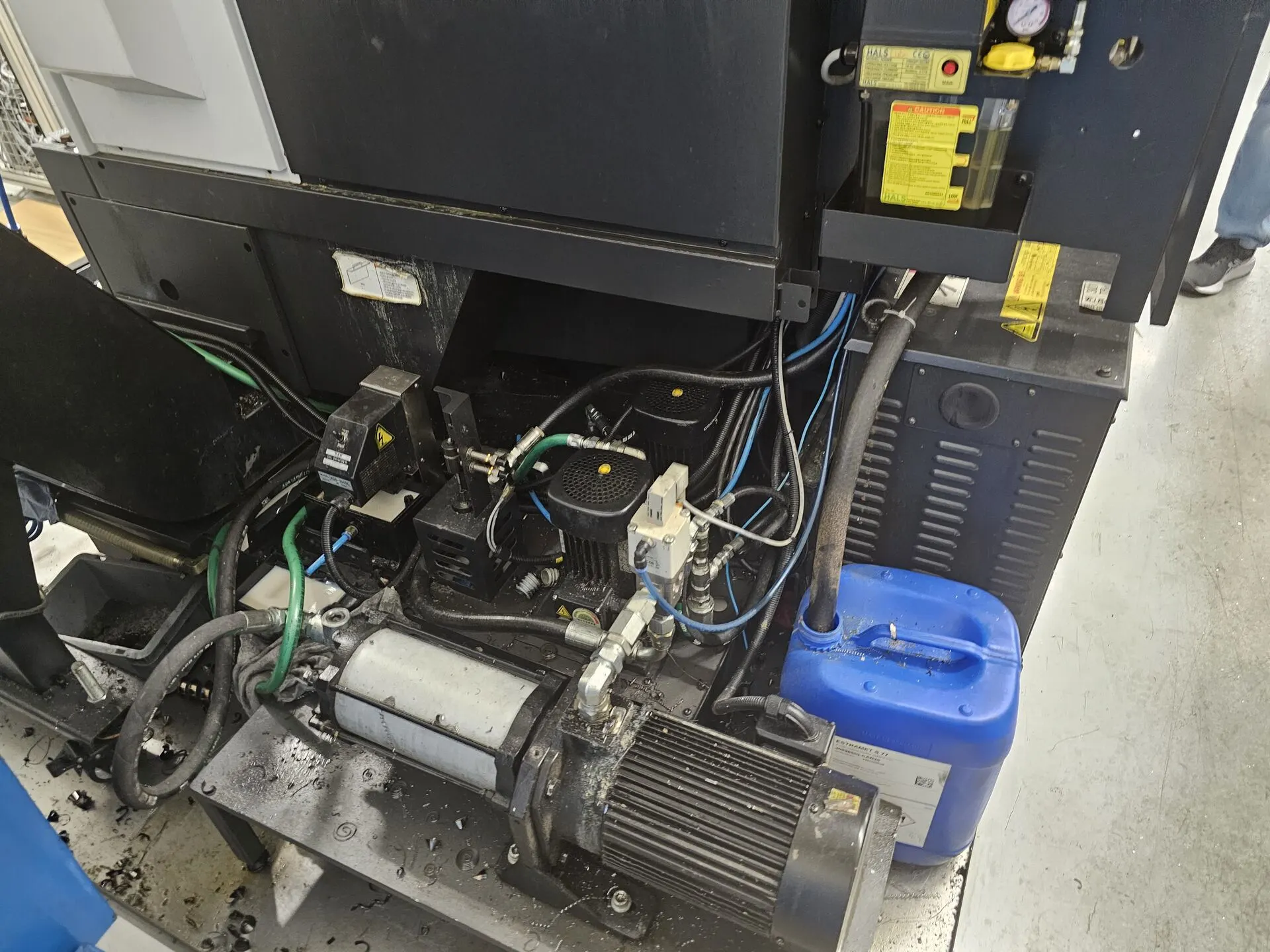

- High pressure pump #1: 5.0 bar – 50 Hz / 1.8 kW

- Panel filter system:

- Filtration: 20 μm

- Flow rate: 30 l/min

- Normal pressure pump #2: 2.0 bar

- High pressure pump #3: 12.0 bar with special valve system for continuous operation between tool changes

- Part ejection system through the counter spindle

- Water through the counter spindle

- Oil separator

- Coolant level sensor

- Parts collector with drawer

- Parts collector with bar conveyor interface

- DOOSAN axis overload system (measuring system)

- Signal tower light

- Robot interface

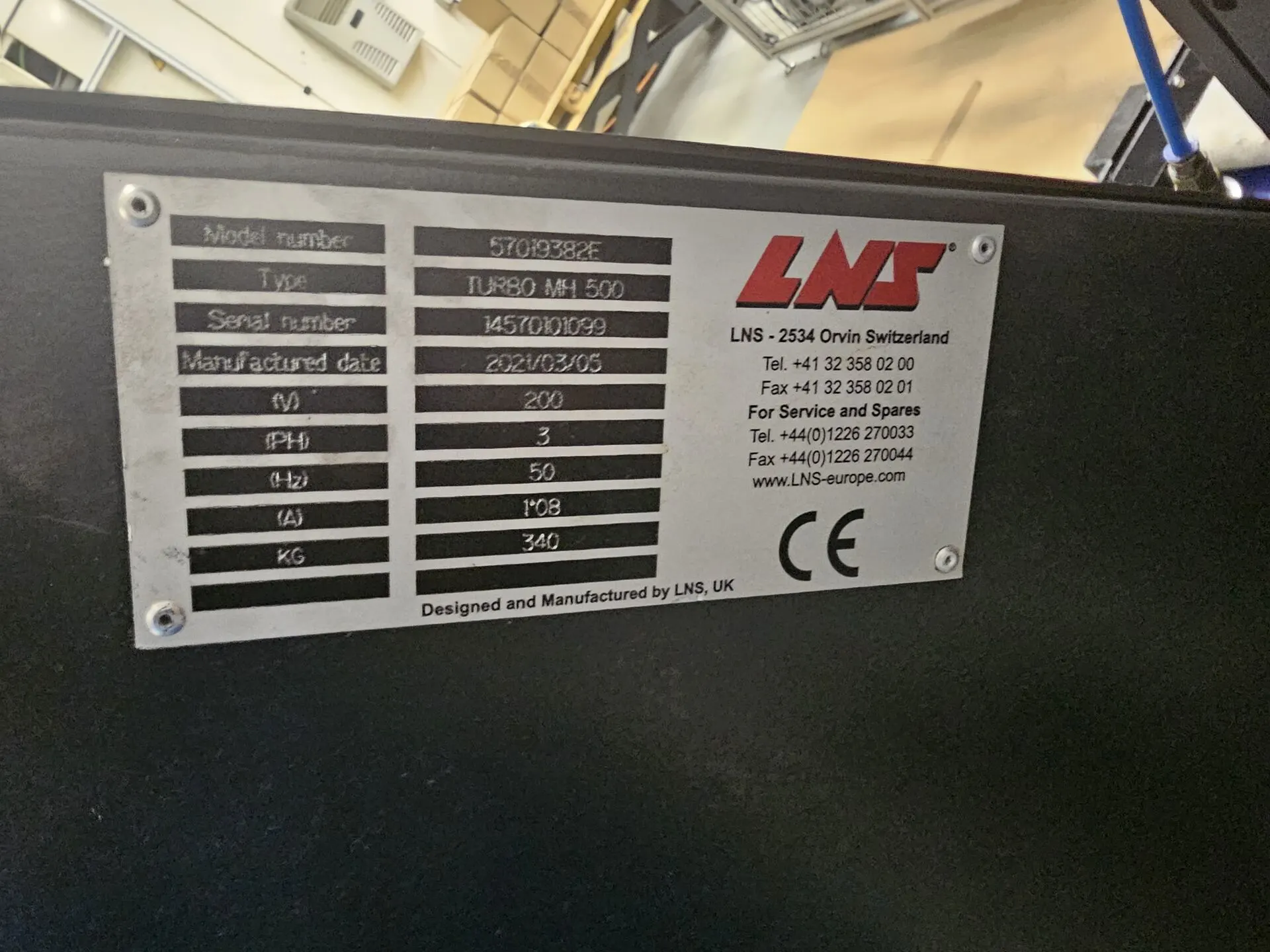

- Profinet chip conveyor system – LNS

- LOSMA air filter system with separation effect

- Water spray gun, with electronic control unit